testing the hardness of annealed copper oxidization|copper annealing timeline : distributors hardness tester, tensile testing machine and simple deflection rig and understand the procedures employed to determine the mechanical properties resulting from different . webTinker Bell nasceu no dia da preparação da primavera e da mudança de uma estação para outra, por isso ela tem o poder de fazer as estações começarem. Ela e suas amigas também fadas cuidam da natureza no reino mágico e conseguem, depois de uma longa aventura, realizar a tão esperada primavera com a ajuda de objetos perdidos da Terra do Nunca.

{plog:ftitle_list}

webAs 37 atrizes de Hollywood mais populares de todos os tempos. Bette Davis, Audrey Hepburn e Meryl Streep são apenas algumas das lendárias atrizes que marcaram as suas gerações em Hollywood através de personagens icônicos em filmes célebres que se tornaram verdadeiros clássicos da Sétima Arte. Com tantas atrizes lendárias que já .

Annealing at high temperatures can remove the effects of strain-hardening via microstructural changes that generally occur in the following sequence: recovery, recrystallization and grain growth.This experiment demonstrates the process of work hardening in a copper, that is, hardening the metal by deformation. If an appropriate furnace is available, it also demonstrates the softening .The ASTM E384 test method was followed during the hardness test. The results show that annealing and applying two passes of the ARB process reduce the grain size by 37%, which .The Rockwell test (Table 1) is used for both ferrous and nonferrous materials, which have been annealed, hardened, case hardened or tempered. Sheet materials in heavier gages and .

hardness tester, tensile testing machine and simple deflection rig and understand the procedures employed to determine the mechanical properties resulting from different . Fabrication of Copper alloy C101 Cold Working of Copper alloy C101. Copper alloy C101 can be readily cold worked. When in the annealed condition, it can be readily bent to shape and has excellent ductility. It work .sion). On the contrary, A annealed copper (* 30 HRF) is very weak (bad for winding), but has good conductivity (102.1 IACS), good for power transmission. Therefore, in this paper we have . An evident and rapid drop of micro-hardness is observed when annealed at 573 K and recrystallization process appears at 120 min (Fig. 5c-iii).

Explore the various heat treatment methods for copper and copper alloys, including homogenizing, annealing, stress relieving, and precipitation hardening. Learn how these . The morphology and hardness behavior of the 0.25-μm thick, chemical vapor-deposited (CVD) copper on SiO 2 on top of Si substrates annealed under oxygen and nitrogen .An Instron testing machine was used with a crosshead speed of 0.02 in. per min. Test procedures are described by R.A. Warren and R.P. Reed in NBS Monograph 63. . Zirconium Copper: Annealed, 950 C; cold drawn 85 to .Explore the various heat treatment methods for copper and copper alloys, including homogenizing, annealing, stress relieving, and precipitation hardening. Learn how these processes can enhance the properties of copper alloys, such as strength, ductility, and hardness. Understand the specific conditions required for each treatment and their effects on .

Beryllium copper is a ductile, weldable, and machinable alloy.Like pure copper, it is resistant to non-oxidizing acids (such as hydrochloric acid and carbonic acid) and plastic decomposition products, [further explanation needed] to abrasive wear, and to galling.It can be heat-treated for increased strength, durability, and electrical conductivity. . Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Mild steel, copper alloy, aluminum alloy, malleable cast iron: HRC: Diamond cone: 1471: 20-70: Quenched steel, quenched and tempered steel, deep case hardened steel: . Annealed copper alloy: K: φ3.175mm .Chemical Composition; Elements; Cu (1,2,3) Pb Zn Fe P Ag As O Sb Te (1) This is a high conductivity copper which has, in the annealed condition a minimum conductivity of 100% IACS except for Alloy C10100 which has a minimum conductivity of 101% IACS.

hardness of various tempers of sheet and strip are in Table 5. . Annealed 75-90 517-620 25-50 172-345 60-35 110-149 60-80 Hot-Finished (except Hexagons over 2 1/8 inches and Angles) . aHeld at -110°F for several hours prior to testing at room temperature.

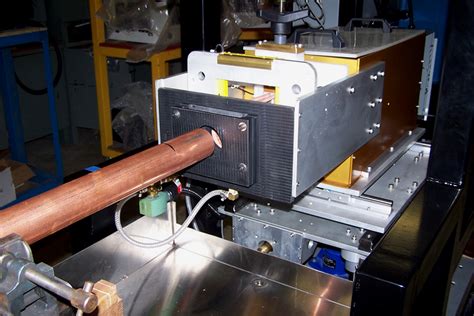

copper wire annealing

Tin ned copper is often used in electrical wiring, plumbing, and other applications where corrosion resistance is important. Annealed Copper vs Tinned Copper. Annealed copper is soft, malleable, ductile, and has a high electrical conductivity. It is obtained by heating up pure copper until it becomes soft enough to be bent or stretched.Annealing the copper requires a high temperature. Copper melts at 1357Kelvin and annealing generally occurs at greater than half the melting point in degrees K; even higher temperature causes faster annealing (but not past the melting temperature, of course). Typical temperature to use is 400C or 700F. Annealing causes the structure to The rolled specimen with a reduction 75.4% is annealed at three different temperatures 420 °C, 520 °C and 620 °C for 30 min followed by furnace cooling. The effect of annealing temperatures on the hardness is shown in Fig. 4. As the annealing temperature rises, the hardness of the samples will decrease.

Annealing is a heat treatment process that changes the physical and sometimes also the chemical properties of a material to increase ductility and reduce the hardness to make it more workable. The annealing process requires the material above its recrystallization temperature for a set amount of time before cooling.%PDF-1.5 %âãÏÓ 293 0 obj > endobj 319 0 obj >/Filter/FlateDecode/ID[20E6C731EA71FEC578D9712D19FEEAAF>49FEBFE08C659D48BF19F3E034329B87>]/Index[293 34]/Info 292 0 R .The microstructure,phase structure,hardness and oxidation resistance of as-cast and annealed at different temperatures AlxFeCoNiCrTi(x=0.5,1 and 1.5) high-entropy alloys were investigated by using XRD,SEM,DSC and TG.The results show that,with increasing the annealing temperature,Fe2Ti type Laves phase precipitated from Al0.5FeCoNiCrTi and Al1FeCoNiCrTi .calculating the area under the stress strain curve produced during a tensile test. (2) Annealing at high temperatures can remove the effects of strain-hardening via . Here a hardness tester can be used if available. If not a scratch test may used. . Annealed 300°F (149°C) Annealed 600°F (316°C) Copper As Elongated grains seen Annealed .

The 0.2% proof stress and elongation are also defined by the strength level. A minimum hardness (Vickers hardness) is guaranteed by adding the letter H with a following number, e.g. CuNi19Fe1Mn H100. Table 11 shows the tensile strength . Surface hardness increased upon hot corrosion testing because of the formation of brittle phases, such as TiO2 and Na4Ti5O12. . Thermal oxidation improved the hardness of raw samples from 342 ± .All new cartridge brass has had the neck annealed. Military brass is polished before annealing, the patina is oxidation. Most commercial brass is polished after annealing resulting in the patina being removed. Annealing case necks .The samples were characterized by a light microscope (LM). The ASTM E384 test method was followed during the hardness test. The results show that annealing and applying two passes of the ARB process reduce the grain size by 37%, which is significant. It also increases copper hardness by 65% and increases its electrical conductivity by 2.6%.

Analysis and Testing; Engineering, Design, & Fabrication; Material Recycling & Reclamation; All Expertise. . and general solution annealing practices. COPPER-BERYLLIUM ALLOY. Copper-beryllium alloys are available in two basic classes . Some atmospheres can minimize the copper oxidation, like a low dew point (-40°F/-40°C) atmosphere of .1.1. Types of Copper and Properties. The copper most commonly used for sheet and strip applications complies with ASTM B370. It consists of 99.9 percent copper, and is available in six tempers designated by ASTM B370 as: 060 (soft), H00 (cold rolled), H01 (cold rolled, high yield), H02 (half hard), H03 (three quarter hard), and H04 (hard).Copper annealing was being performed in the North American city of Cahokia around 1000–1300 AD. . (reduction of copper; oxidation of superoxide) . Severe deficiency can be found by testing for low plasma or serum copper levels, low ceruloplasmin, and low red blood cell superoxide dismutase levels; these are not sensitive to marginal .

copper annealing worksheet

Learn more about material hardness testing. How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. . Copper: Copper C101 <65 to 105--Mild Steel: Mild Steel S275JR | 1.0044 | Fe [~135] 75- . As machined. Heat treated <365 (solution annealed) 400 to 500 (heat treatment H900) .Laser Annealing: This technique employs laser light as a heating source. It offers precise control over the area of heat application and the rate of heating and cooling, unmatched by conventional techniques. Vacuum Annealing: By utilising a vacuum environment, this annealing avoids oxidation and contamination that can affect material properties . Annealed copper consists mainly of two elements: copper (Cu) and zinc (Zn). Other metals, such as nickel (Ni) and iron (Fe), may also be present depending on the alloy being used. The amount of each element present varies depending on the specific application; some alloys may contain up to 50% Zn while others may only contain 10%.example, changes in hardness and microstructure are shown as a function of rolling. In the process, the concept of hardness is introduced along with hardness testing methods and the relationship (indirect) between hardness and strength. The module is designed such that no test equipment is needed. If test equipment is available, the module

Fig. 5 The relationship between hardness and annealing temperature for cartridge brass. 14.2. Heat treatment of copper. . Fig. 6 Effect of annealing temperature upon oxidation of copper .

In this study, a continuous and dense FeAl/Al2O3 gradient coating was prepared on the surface of 316L stainless steel by hot-dipping aluminizing, vacuum annealing and low-oxygen pressure oxidation. The results showed that when a hot-dipping pure aluminum was applied, the alloy compound layer was composed of (Fe, Cr, Ni)2Al5 and (Fe, Cr, Ni)Al3 phases. When the .

From Fig. 9(a) and (b), it can be seen that after annealing for 1 h, the preferred orientation of aluminum is the crystal plane of {001}, with an texture intensity value of 6.31, the preferred orientation of copper is the crystal plane of {110}, with an texture intensity value of 2.77; from Fig. 9(c) and (d), it can be seen that after annealing .

copper annealing timeline

copper annealing time

Electra Dominica Empregada Safada Ficou Peladinha Na Faxina. 37.2k 5min. Electra Dominica Empregada Gostosa. 169.9k 5min. Electra Dominica Empregada Dom Stica Gostosa. 19.8k 5min. Electra Dominica Empregada Gostosa Trocando De Shortinho. 68.5k 6min. Electra Dominica Empregada Do Xvideos. 64.5k 7min.

testing the hardness of annealed copper oxidization|copper annealing timeline